Take control of your reactor design with DETCHEM

DETCHEM is a suite of tools that accurately and efficiently model most common types of chemical reactors. DETCHEM is not computational fluid dynamics, but the results can be just as accurate and calculated in a fraction of the time.

Stop waiting for results. Faster simulations unlock creativity by allowing for rapid iteration of design concepts. All DETCHEM products have a common set of features that make advanced simulation simple.

Use the mechanisms search tool to find the right DETCHEM mechanism for your needs.

Internal pore diffusion

Discover the secret lives of your catalysts.

Catalysts are often porous materials with massive internal surface area. Internal passageways are generally nanoscale, sometimes resulting in pore diffusion resistances that can increase the local residence time. Selectivity can deteriorate as side products form.

DETCHEM products can optionally model the reaction diffusion equation at every calculation node, with a variety of user-selectable diffusion models. Don't operate blindly. Model what happens inside your catalytic beds and wall coated catalysts and use these insights to design your reactor and troubleshoot your system.

Kinetics models

Detailed microkinetics or customized rate expressions. Your choice.

DETCHEM supports gas phase and surface reaction models - including and surface phase reactions enabled simultaneously.

Microkinetics models are simple to incorporate. Choose from many published microkinetics models available online at detchem.com, or create your own detailed model.

Alternatively, write custom kinetics expressions with the easy-to-use User Defined Function (UDF) feature. The UDF structure is intuitive and makes it easy to program complicated rate expressions in a free-form manner - no compilation required.

Use the mechanisms search tool to find the right DETCHEM mechanism for your needs.

# Calculate the denominator term

H2OFactor = Ph2o/Ph2

QSMR = 1 + Kco*Pco + Kh2*Ph2 + Kch4*Pch4 + Kh2o*H2OFactor

QSMRsq = QSMR * QSMR

# Rate 1 numerator

term1a = krate1 / Ph2^2.5

term1b = Pch4*Ph2o - ((Ph2^3)*Pco/Ke1)

# Rate 2 numerator

term2a = krate2 / Ph2

term2b = (Pco * Ph2o) - ((Ph2 * Pco2) / Ke2)

# Rate 3 numerator

term3a = krate3/Ph2^3.5

term3b = (Pch4*Ph2o^2) - ((Ph2^4)*Pco2/Ke3)

# Catalyst density, kg/m3

rhoCat = 762

# Rate expressions

r1 = rhoCat * term1a * term1b / QSMRsq

r2 = rhoCat * term2a * term2b / QSMRsq

r3 = rhoCat * term3a * term3b / QSMRsq

<UDF-Reaction>

CH4 + H2O > CO + 3 H2

variable="r1"

</UDF-Reaction>

<UDF-Reaction>

CO + H2O > CO2 + H2

variable="r2"

</UDF-Reaction>

<UDF-Reaction>

CH4 + 2 H2O > CO2 + 4 H2

variable="r3"

</UDF-Reaction>Key Features

DETCHEM is a full-featured solver for steady state packed bed and empty tube reactors, with many features built-in.

Simulation capabilities

High performance

Very fast compared to 2D or 3D CFD.

High accuracy

Built-in correlations calculate the overall heat transfer coefficient for packed beds and empty tubes.

Multi platform support

Run DETCHEM on the platform of your choice - Windows, Linux or macOS.

Advanced physics

Internal catalyst mass transfer

Discover the secret lives of your catalysts. Model internal diffusion resistances with either the 1D reaction diffusion equation or the effectiveness factor model.

Gas phase and surface reactions

Take homogeneous and heterogeneous reactions into account in your calculations - either simultaneously or separately.

Thermodynamic and Transport properties

Calculate transport properties from kinetic theory of gases, and thermodynamic properties from NASA style polynomials.

Versatile configuration

Freedom of Kinetics expressions

Microkinetics? Complicated custom rate expression? No problem.

Custom units and dimensions

Enter your input values in the (physical) units you work with - no need to convert to SI units.

Multiple axial reactor sections

Divide your reactor into multiple sections, each with its own set of properties and conditions.

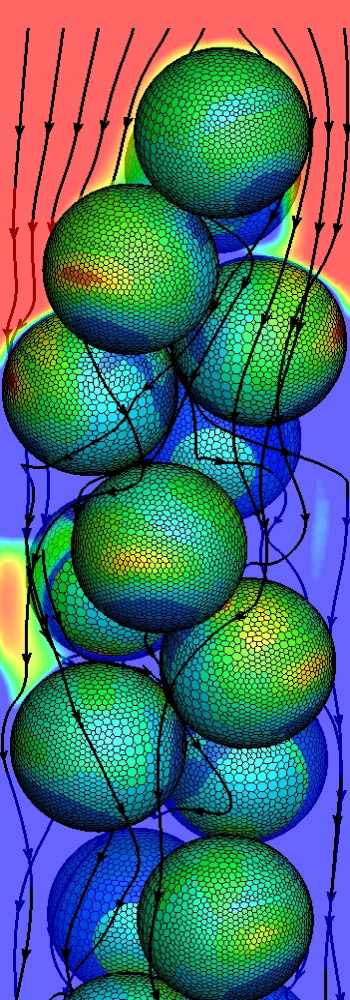

Detchem PBR

Packed Bed Reactors

DETCHEM PBR includes all the common features of the DETCHEM software suite, including the pore diffusion model to that allows you to “see inside” catalyst pellets.

DETCHEM PBR also includes UDF kinetics that make tough-to-program kinetics easy to implement.

High accuracy

Skip CFD.

Accurate packed bed heat transfer built-in.

In many situations, a 1D packed bed simulation can accurately predict performance results, including when there are non-isothermal radial temperature gradients. Using built-in heat transfer correlations, DETCHEM PBR closely matches 2D porous media CFD and 3D Particle Resolved CFD (PRCFD) results for the Dry Reforming of Methane.

DETCHEM PBR is a fraction of the cost, without the complexity and hassle of CFD.

- 3d CFD

252x - 2d CFD

30x - PBR

baseline

Smaller is better.

Fast simulations

Stop waiting for results. Design faster.

With DETCHEM PBR simulations typically take just seconds, usually 10X to 100X times faster than CFD. The Dry Reforming example above required 42 minutes with 400 cores for 3D Particle Resolved CFD, 5 minutes with one core for porous media 2D CFD, and just 10 seconds for DETCHEM PBR on one core.

Fast simulations allow engineers to be more creative. Test more conditions and optimize your design faster with DETCHEM PBR.

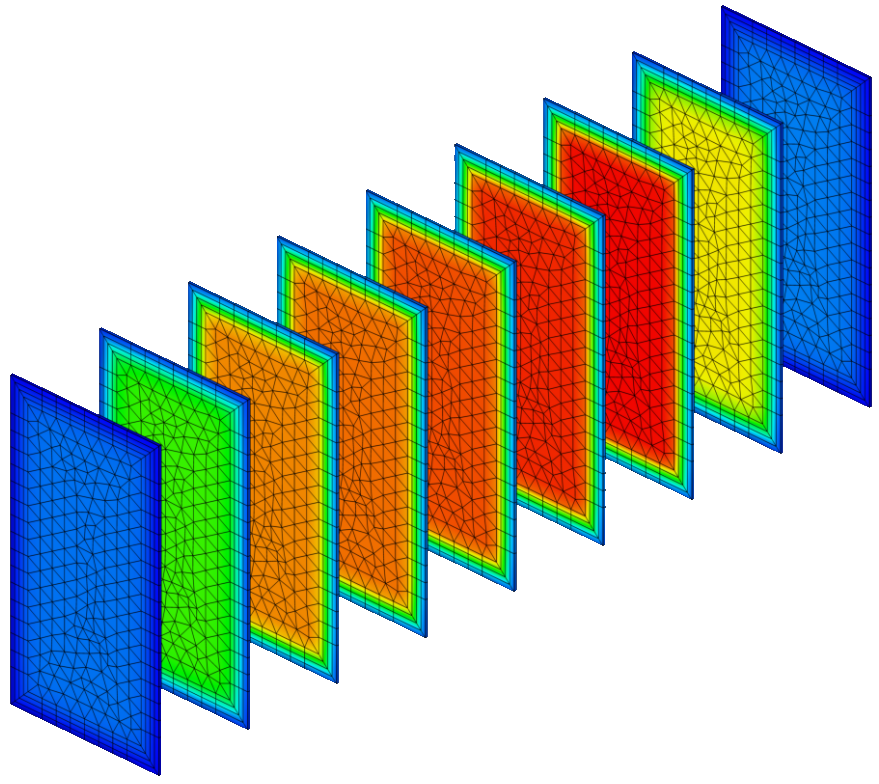

DETCHEM CHANNELS

Explore the capabilities of DETCHEM CHANNELS, a powerful module designed for simulating 2D wall-coated reactors like monolith or microchannel reactors.

Wall coated reactors

Monoliths and Microchannels

Model your monolith reactor at multiple scales with DETCHEM CHANNEL, RESERVOIR and MONOLITH. DETCHEM CHANNEL simulates a 2D wall coated reactor, e.g., a channel in a monolith or a microchannel reactor.

DETCHEM RESERVOIR is a pseudo-steady state (transient) version of CHANNEL, perfect for storage reactions in monolith or microchannel reactors, where accumulation of a specie over time on a surface is important.

DETCHEM MONOLITH is a pseudo-steady state (transient) solver for calculating many CHANNELs, including the conductive heat transfer in the solid (monolith) matrix. With DETCHEM MONOLITH, model your entire DETCHEM CHANNEL.

All the accuracy. Fraction of the time.

CHANNEL can model flow, heat transfer, and reactions in any planar or cylindrical single channel reactor. Surface reactions (i.e., wall coated catalysts) and gas phase reactions are supported.

CFD

8 minutes to converge with one core

Channel

~2 seconds to calculate on one core

DETCHEM MONOLITH

DETCHEM MONOLITH extends the capabilities of DETCHEM CHANNEL to entire 2D or 3D monolith reactors, offering comprehensive modeling of:

- 1. Transient surface reactions

- 1. Heat transfer between solid walls and fluid channels

- 2. Conduction within solid walls

Additionally, DETCHEM MONOLITH accommodates time-dependent inlet conditions, allowing for realistic simulations of dynamic reactor environments.

As with other DETCHEM products, MONOLITH is not CFD. Using advanced technique to cluster channels with similar temperature, pressure and composition, MONOLITH can produce solutions many times faster than traditional CFD approaches.

Solid Oxide Cells

Optimize the design of solid oxide fuel and electrolysis cells with DETCHEM SOC.

Multiscale methodology

Design cells. Test stacks.

DETCHEM SOC simulates button cells, single repeating units and stacks of cells. Calibrate your own model on just a few button cell experiments, or draw from our panel of published models. This is the only prerequisite to perform simulations at any scale.

DETCHEM SOC is used in scientific studies to evaluate the performance of novel cell materials, even on a stack level. Stack performance can be estimated before a single stack has been manufactured.

Insight into complex chemistry

Get to know your cells

Electrochemistry, surface chemistry, charge transport, gas flow and temperature changes are all simulated by DETCHEM SOC, from the surface of the catalyst to the insulation of the stack. No matter which part of the system you are trying to improve, the model will provide the data to understand it.

DETCHEM SOC lets you look into the electrodes to find where the reactions actually happen.

Transient simulations

Simulate dynamic scenarios

Since electrochemical systems are dynamic, all DETCHEM SOC models are transient. It allows the simulation of button cell impedance spectra, a load change of a cell or the start-up process of a stack.

Cell start-up can hide surprising behavior. DETCHEM SOC can help you understand it.

DETCHEM UTILITIES

DETCHEM UTILITIES provide quick access to key physical and transport constants, equilibrium compositions, and kinetics source terms with handy 0D calculators.

DETCHEM EQUIL

Use DETCHEM EQUIL to calculate equilibrium compositions of species. It is easy to sweep over a range of temperatures to readily produce plots for adiabatic, isothermal, and other thermodynamic processes.

DETCHEM GASPROBE

DETCHEM GASPROBE quickly calculates specie and mixture averaged properties, along with the gas phase source term, for a given temperature, pressure, composition and kinetics mechanism. GASPPROBE is helpful, for example, to quickly calculate accurate properties for spreadsheet calculations.

heat capacity [J/kg K] enthalpy [J/kg] entropy [J/kg K]

NO 1.16144502E+03 3.98033058E+06 8.48984838E+03

O2 1.11232123E+03 9.30481633E+05 7.81081865E+03

NO2 1.16563315E+03 1.65345571E+06 6.59683859E+03

O 1.30515344E+03 1.67655879E+07 1.19061303E+04

N2 1.20326289E+03 1.00380352E+06 8.35843383E+03

average 1.19745604E+03 1.10405497E+06 8.17725487E+03

mix diff coeff [m^2/s] viscosity [kg/m s] heat cond [J/m K s]

NO 2.15500398E-04 4.83687258E-05 7.94899428E-02

O2 2.20299385E-04 5.39859100E-05 8.48080255E-02

NO2 1.82631959E-04 5.71341364E-05 9.00908335E-02

O 3.39077003E-04 6.30648684E-05 1.22899213E-01

N2 2.99930563E-04 4.67350570E-05 7.97204189E-02

average 4.76882120E-05 8.07031163E-02

mixture density [kg/m^3] Prandtl # [-]

average 2.80769884E-01 7.07587761E-01

Coverage after 100.00000000000000s

PT(s) 0.44510821735842770

O(s) 0.55478603279999639

NO2(s) 1.0550724460620868E-004

NO(s) 1.3443609410418216E-007

Fluxes at surface mole/(m**2 s) kg/(m**2 s)

NO 0.44214221E+01 0.13266963E+00

O2 0.22107111E+01 0.70740102E-01

NO2 -0.44214221E+01 -0.20340974E+00

O 0.00000000E+00 0.00000000E+00

N2 0.00000000E+00 0.00000000E+00

Net surface mass flux 3.0531133177191805E-016 kg/(m**2 s)

d(Coverage)/dt after 100.00000000000000s

PT(s) -0.14367592E-08

O(s) 0.15347201E-08

NO2(s) -0.91430131E-09

NO(s) 0.19592171E-09

DETCHEM SURFPROBE

DETCHEM SURFPROBE is used to calculate surface fluxes for a given mechanism, time scale, composition, temperature and pressure. This is a powerful tool for developing and checking surface reaction mechanisms.

DETCHEM CFD

Discover the power of DETCHEM CFD, where core functionalities like UDF kinetics, internal pore diffusion, and microkinetics are applied to any geometry, enhancing computational fluid dynamics with precision and speed.

Computional Fluid Dynamics

Apply core DETCHEM functionalities, like UDF kinetics, internal pore diffusion, and DETCHEM microkinetics to any geometry.

DETCHEM CFD also has many features, such as external coupling to faster DETCHEM solvers, to cell agglomeration for chemistry acceleration, to produce accurate results more quickly.

CONCENTRATION CH4

SURFACE RATE CH4

Additional Features

Chemistry

- Model homogeneous and heterogeneous reactions

- Use DETCHEM microkinetic mechanisms

- UDF’s for chemical kinetics

- Discover the Secret Life of Catalysts with internal pore diffusion models for catalytic walls and porous media

- Select mixture averaged and full multicomponent diffusion (Maxwell-Stefan equations)

- Accelerate simulations with ISAT for surface reactions and cell Agglomeration for surface and gas phase reactions

Packed bed heat transfer

- Simulate Packed Bed Reactors in 1D, including radial heat transfer, axial diffusion, and axial conduction effects

- Automatically calculate effective thermal conductivity for 2D porous media simulations of packed beds

- UDF’s for chemical kinetics

- Account for external heat and mass transfer resistances

And so much more…

- Automatically use the kinetic theory of gases to calculate transport parameters

- Apply different mechanisms to different porous media and wall coated catalysts

- UDF’s for chemical kinetics

- Simulate pyrolysis and other reactions where materials are deposited on or vaporized from a surface