DETCHEM Applications

A non-exhaustive list of DETCHEM applications in the fields of catalysis, reactor design, and materials synthesis.

CPOX Reactor Modeling (DUO)

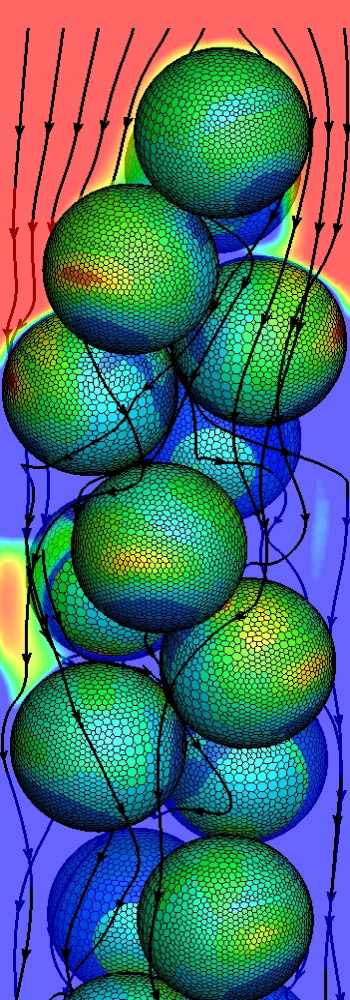

Modeling of a fixed bed reactor

Modeling of a fixed-bed catalytic tube reactor with 86 particles for catalytic partial oxidation (CPOX) process with the code DUO=OpenFOAM+DETCHEM. The small tube-to-particle diameter ratio of 2 requires the use of 3D Particle-Resolved Computational Fluid Dynamics (PRCFD) models to capture the salient physics, including heat and mass transfer effects. The plot shows on left side a slice and isosurfaces of methane concentration. On the right side some streaklines and the reaction rate of methane on the surface of the particles. Flow is from top to bottom.

CONCENTRATION CH₄

SURFACE RATE CH₄

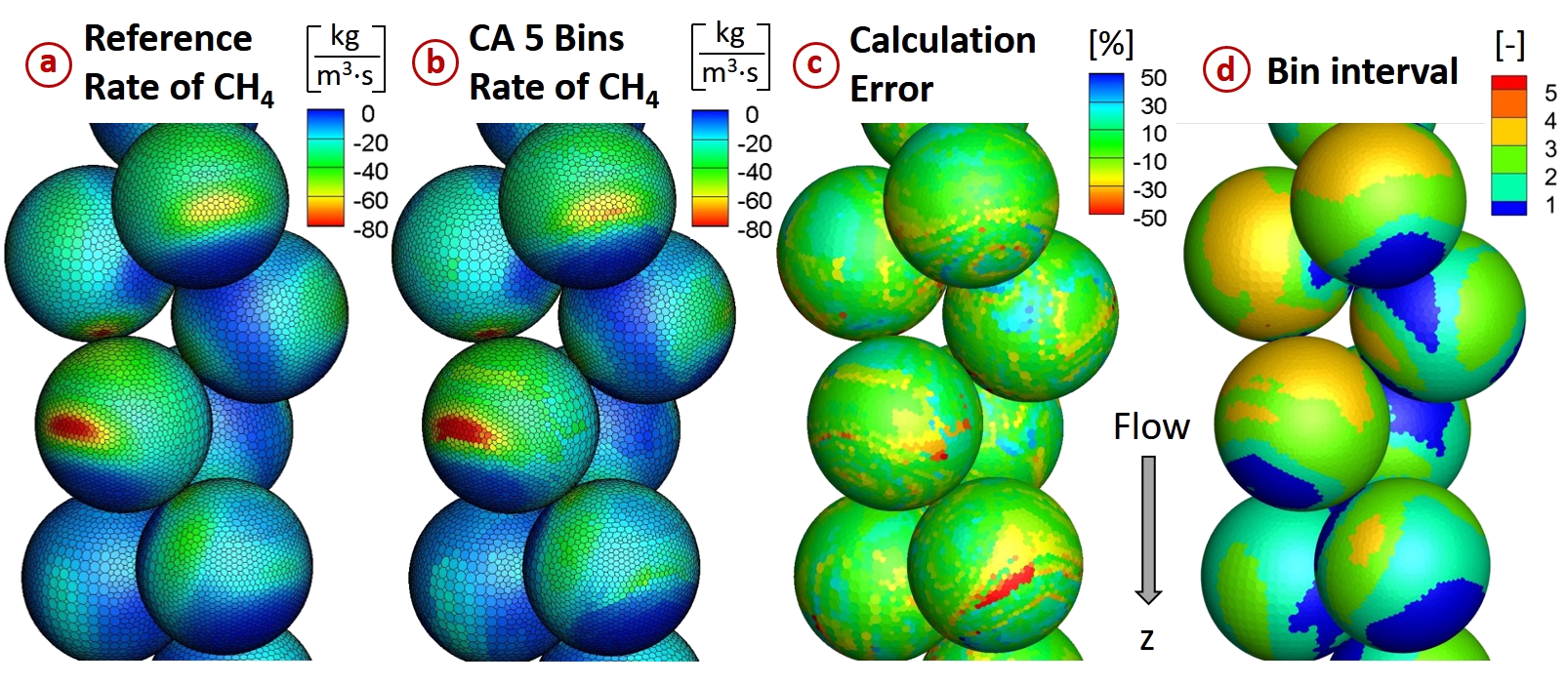

The effect of Cell Agglomeration (CA) technique on calculation speed and accuracy was investigated. Speedup factor was between 7 for catalytic partial oxidation (CPOX) and 35 for dry reforming of methane (DRM). Picture shows CPOX case: a.) conversion rate of methane (reference case), b.) conversion rate of methane (CA case), c.) local calculation error, d.) bin interval for rate of methane using 5 bins.

Temperature field of the fluid part and the two solid bodies (only the second one is coated). Fluid part and solid regions are solved with OpenFOAM® whereas the detailed surface reaction is calculated by DETCHEM. Additionally, some streaklines are plotted. The slice at the end of the calculation domain shows the distribution of the velocity into z-direction.

Solid Oxide Fuel Cell (SOFC) Stack Modeling

Modeling thermal cycling behavior in high-power density SOFC stacks

Simulating the start-up behavior of a 10 kWe-class high-power density metal-supported Ni-CGO/CGO/YSZ/CGO/LSCF-CGO 120-cell stack for stationary and mobile power generation. Shown is the temperature profile of the stack solid phase including a microporous silica-based insulation layer at the stack’s periphery. The model includes convective and radiative heat loss to the ambient surroundings.

Flow Field Modeling (DUO)

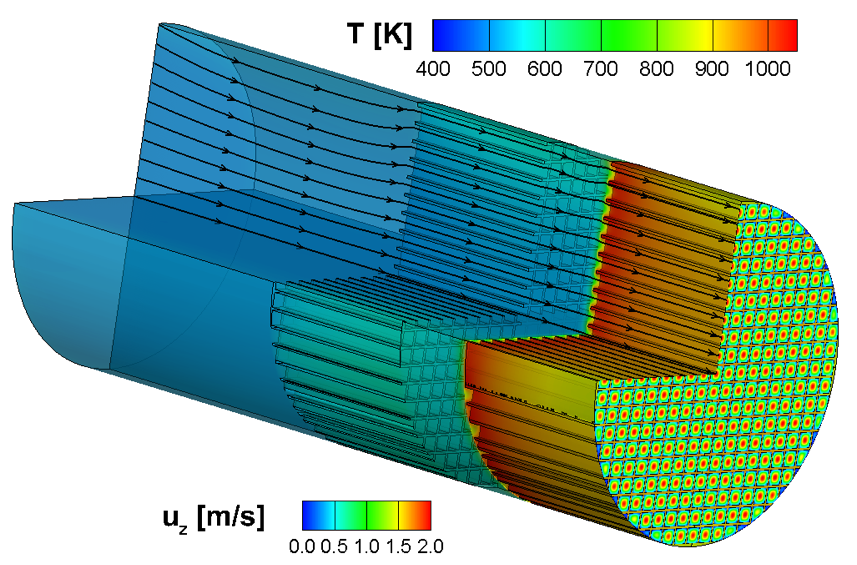

Modeling of flow field up and downstream of a monolith

Two coupled flow domains using different turbulence models and numerical parameters have been solved. The pressure loss of each of the 1100 channels of the monolith (one quarter of catalyst assembly) was derived on basis of a developed laminar flow.

Materials Synthesis

Production of advanced carbon materials by pyrolysis and chemical vapor infiltration

Numerical predicted temporal development of 2d spatial of density and species concentration profiles within in carbon felts. Based on multi-step reaction and deposition models including the hydrogen inhibition model of pyrocarbon growth, transient 2D simulations of chemical vapor infiltration of methane were carried out by a finite element method (FEM).

High Temperature Catalysis

Transient behavior of partial oxidation monoliths

Light-off of an extruded monolith coated with rhodium as used for partial oxidation of methane to synthesis gas. A cold methane/oxygen/nitrogen mixture flows from left into the preheated cold monolith. The figures reveal the calculated temperature distribution of the monolith and the methane, hydrogen, and water concentrations within three single monolith channels after 2 and 120 seconds of reactor operation.

Automotive Catalytic Converters

Simulation of the thermal behavior of a three-way catalyst during a driving test

Light-off of an extruded monolith coated with rhodium as used for partial oxidation of methane to synthesis gas. A cold methane/oxygen/nitrogen mixture flows from left into the preheated cold monolith. The figures reveal the calculated temperature distribution of the monolith and the methane, hydrogen, and water concentrations within three single monolith channels after 2 and 120 seconds of reactor operation.